Why have LED lamps become the mainstream choice in the horticultural lighting market?

What is the difference between LED lighting technology and other traditional lighting technologies such as HPS (high pressure sodium lamps), MH (metal halide lamps) and CFL (fluorescent lamps)?

Let's take a look at the differences between these technologies today.

1. High Pressure Sodium Lamp (HPS)

Historical Origin

Let's go back to the 1960s, when Philips made a big news - they developed and launched the High Pressure Sodium Lamp (HPS). Initially, this lamp was mainly used to illuminate streets and outdoor places. It is both efficient and durable, and soon it was used in various industrial and commercial environments.

Technical Principle

So, how does the HPS lamp work?

In short, the HPS lamp is a gas discharge lamp.

What is a gas discharge lamp?

It relies on the arc generated in sodium vapor and other inert gases (such as xenon) to achieve bright light. What does it mean?

When a high voltage current passes through the lamp tube, an arc will be struck between the electrodes, causing the sodium to evaporate, and then emitting strong yellow and orange light. This light is mainly concentrated in the yellow-red spectrum, like a beam of golden sunlight, which is particularly suitable for plants to bloom and bear fruit.

The main components of HPS lamps include:

Tube: Contains sodium and inert gas.

Electrode: Where the arc is generated.

Starter and ballast: Used to start and stabilize the current.

2. Metal halide lamp (MH)

Historical origin

In the late 1960s, this kind of bulb quietly appeared, and in the early stage it was mainly used to illuminate stadiums and large industrial facilities. At that time, the stadiums were brightly lit, thanks to it. Because its spectrum is close to daylight and is particularly natural, MH lamps were quickly snatched up by the horticultural and plant lighting industries.

Technical principle

In fact, MH lamps are a bit like high-pressure sodium lamps, both of which are gas discharge lamps.

But MH lamps are more fancy, and they emit light by generating an arc in metal halide vapor.

The lamp tube is filled with various metal halides, such as mercury, sodium, thallium, indium, etc. When current passes through the lamp tube, these chemical elements evaporate and emit colorful light.

Unlike the yellow-red light of HPS lamps, MH lamps have a more comprehensive spectrum.

MH lamps are very suitable for the vegetative growth stage of plants and can promote the healthy growth of leaves and stems. Although MH lamps have a high light efficiency, their lifespan is relatively short.

The main components of MH lamps include:

Tube: Contains metal halides and inert gases.

Electrode: Where the arc is generated.

Starter and ballast: Used to start and stabilize the current.

Due to its strong blue light output

3. Fluorescent lamps

Historical origins

The origin of fluorescent lamps can be traced back to the late 19th century and early 20th century. However, it was General Electric in the 1930s that really made it practical. It was their successful development of practical fluorescent lamps that made this technology quickly popular. From offices to schools to homes, fluorescent lamps are everywhere.

Technical principle

So, how do fluorescent lamps work?

Its technical principle is actually not complicated. Fluorescent lamps use electric current to excite mercury vapor to produce ultraviolet rays, and then convert ultraviolet rays into visible light through phosphors.

Fluorescent lamps have high light efficiency and low heat generation, and will not burn plants even if they are exposed to close range. The initial investment cost is also low, which is suitable for tight budgets, indoor planting and small plant growth.

The main components of fluorescent lamps include:

Tube: Contains mercury vapor and phosphor.

Electrode: Where the current passes.

Ballast: Used to start and stabilize the current.

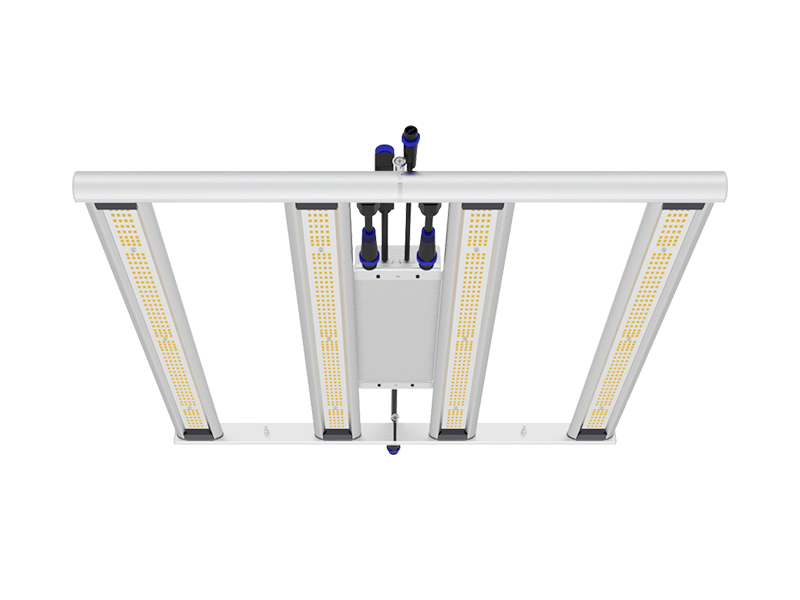

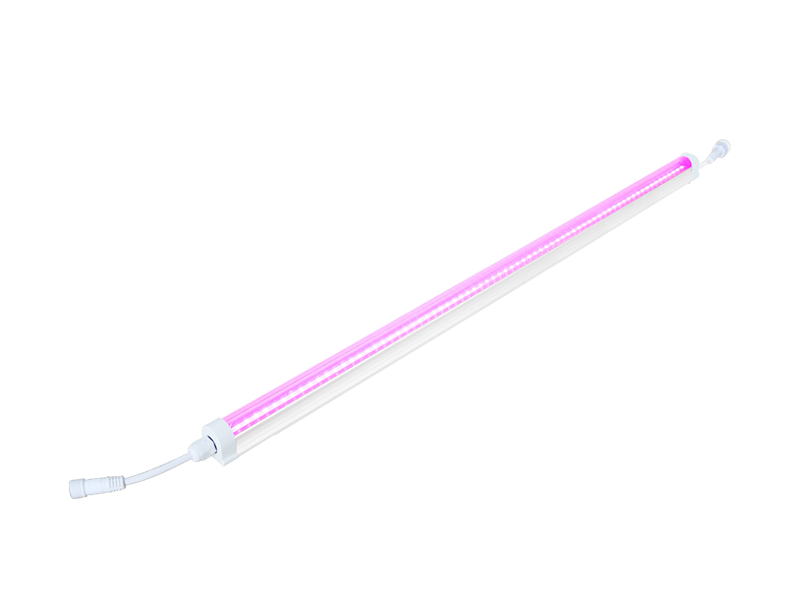

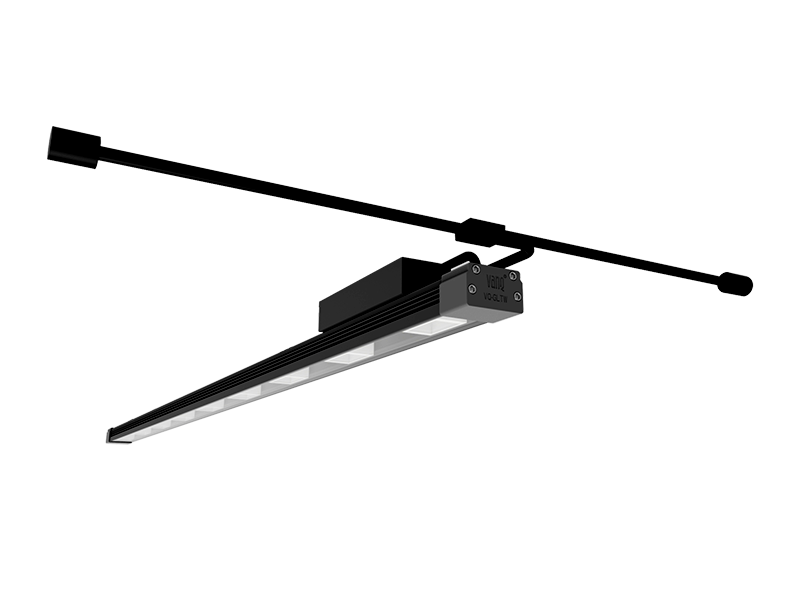

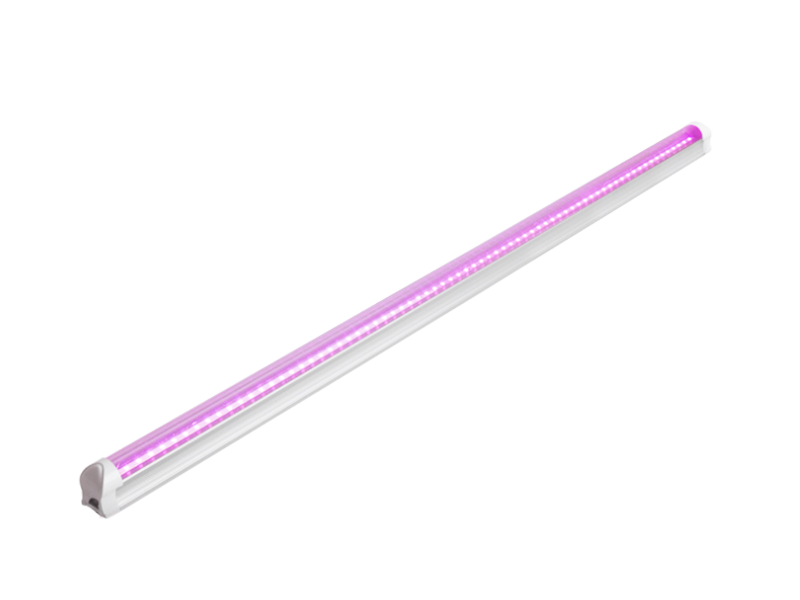

IV. LED lamps

Historical origins

LED lamp technology can be traced back to the early 20th century, but it was not until the 1960s that Nick Holonyak made the first visible light emitting diode. After that, LED technology developed rapidly like a rocket, and the light efficiency continued to improve, gradually breaking into the lighting industry.

Technical principle

LED lamps emit light through semiconductor materials after applying voltage. Simply put, when current passes through the LED, electrons and holes meet and "fall in love" at the positive and negative electrodes of the semiconductor and combine together. This combination releases energy, just like popcorn, "pop", and is manifested in the form of light.

More interestingly, different semiconductor materials can emit different colors of light.

Ordinary lamps often have too strong light, which may even burn your delicate seedlings? LED plant lights are not like this. Their light is gentler, which will not cause the leaves to scorch, ensuring the healthy growth of plants.

Ordinary lighting equipment consumes a lot of electricity, while LED plant lights can save 10% to 20% of electricity bills. So how much money can you save every month?

Compared with other HPS, MH, and fluorescent lamps, LED lamps have basically no defects except for a slightly higher initial investment cost. This may be the reason why LED lamps have become the mainstream of modern agricultural lighting.

The main components of LED lamps include:

Semiconductor chip: the core part of the light.

Electrode: where the current passes.

Lens and packaging materials: used to focus light and protect the chip.