With the fast development of indoor horticulture, artificial lighting technologies has been widely used in indoor and greenhouse plant growing for a long time. In order to choose the best light source for plant growth, it is necessary to understand the history, characteristics, luminescent mechanism, and applicability of typical light sources.

1.Three Horticultural Lighting Technologies

Three major light source technologies have been used in the horticultural lighting system: incandescence (incandescent lamp), an electrical discharge (fluorescent, HID), and solid-state light sources (LED, OLED). The first and two are known as “legacy” technologies, and the third is considered as modern technologies. Here are the differences between LED grow lights and other plant lights.

1.1 Fluorescent lamp

Fluorescent Grow Light

The compact fluorescent lamp (CFL) is considered as the second generation of an artificial light source, which had the greatest development in lighting since the incandescent lamp. There are three main types of fluorescent lamps: cold cathode, hot cathode, and electroluminescent lamps. They all use phosphors excited by electrons to create light. The difference is that electroluminescent lamps use fluorescence. It has been widely used in hotels, offices, shops, hospitals, libraries, advertising, family, and plant cultivation for 78 years of history since commercial use.

The cold and hot cathode lamps consist of a glass discharge tube filled with an inert gas (usually argon) at low pressure, the fluorescent coating on the inside, a tungsten electrode in each side, a ballast only or ballast with starting switch. Fluorescent lamps work by ionizing mercury vapor in the glass tube. This causes electrons in the gas to emit photons at UV frequencies. The UV light is converted into standard visible light using a phosphor coating on the inside of the tube.

1.2 High-intensity Discharge Lamp(HID)

HID Grow Light

High-intensity discharge (HID lamps) lamps are known as the third generation of the artificial light source. They are also a type of electrical gas-discharge lamp mainly including metal halide, high-pressure sodium, low-pressure sodium, and mercury-vapor lamps. HID lamps are applicable for large square.

HID lamps produce light by striking an electrical arc across tungsten electrodes housed inside a transparent and specially designed fused quartz or fused alumina arc tube. This tube is filled with both gas and metal salts. The gas aids in the arc’s initial strike. Once the arc is started, the metal salts are heated and evaporated to produce the light, forming a plasma. Like fluorescent lamps, a ballast is necessary for HID lamps to start and maintain the discharge arc.

Metal halide (MH) lamp and high-pressure sodium (HPS) lamp are the typical HID lamps. HPS is the one that has been widely used in horticulture.

Metal Halide Lamp(MH)

MH Grow Light

Metal halide lamp (MH) is a kind of HID light source. It is popular due to its great color rendering index and high efficiency. The most prominent applications are streets and squares, stadiums, industrial buildings, exhibition centers, shopping malls, docks and railway stations.

Stabilizing the MH lamp arc and color was the main problem in history. The lamp uses mercury vapor to create the powerful light but includes other halide salts (fluorine(F), chlorine (Cl), bromine(Br), iodine(I) and astatine (At)) to improve the color. A halogen is a monovalent element that readily forms negative ions. A halide is a chemical compound of a halogen combined with an electropositive element.

The argon gas strikes an arc at a low temperature, so the current can pass through the starting electrode to the main electrode. The initial arc is weak, and it can heat up the mercury into a vapor. So the more molecules of the gas ionize, the more current passes through the arc. When the arc reaches the other main electrode, the current will stop flowing through the starting electrode. Meanwhile, the halides vaporize and dissociate. The metal atoms diffuse away from the arc and recombine with the halogen before they damage the silica or electrodes. Finally, the lamp is fully warmed up and produces its white light.

Some critical materials are used for MH lamps. Under high temperature and pressure, fused quartz is adapted due to a high melting temperature instead of the silica in a normal glass. To increase the lifetime, tungsten made electrode is also treated with radioactive thorium. Borosilicate glass is used in the outer envelope to insulate as well as filter out UVB radiation. Molybdenum is used in the seal of the discharge tube to avoid corrosion and high temperature.

High-pressure Sodium Lamp(HPS)

HPS Grow Light

High-pressure sodium (HPS) lamp is a kind of HID lamp with high lumen output and high efficiency. It has been widely used in airports, industrial and mining enterprises, parks, highways, squares, streets interchange, and plant growth.

The sodium lamp with higher pressure in the arc tube could achieve higher efficiency. Which kind of material could stand the corrosive effects of sodium under the high pressure and temperature is the main problem. Later, aluminum oxide ceramic was adopted. HPS lamps consist of a narrow arc tube supported by a frame. Sodium, xenon, and mercury are used inside the arc tube. The lamp starts an arc through xenon gas by a pulse of high voltage via a ballast. Then the arc heats up the mercury-like MH lamps. The sodium is the last material to vaporize (over 240℃). The mercury helps add a blue light to the pure yellow of sodium. The sodium is mixed with other impurities to create a nice white light.

1.3 Light Emitting Diode(LED)

Solid-state light sources are a kind of modern light sources, including Light Emitting Diode (LED) and Organic Light Emitting Diode (OLED). LED is known as the fourth generation of artificial lighting sources, which has about 60 years of history from the first infrared LED patented in 1961 . In 1962, the first practical visible-spectrum LED was developed. The first high-power (1W) LEDs were developed in the late 1990s. It is a new technology and has been developed rapidly in the last decade. Early LEDs emitted low-intensity infrared or red light and often used as indicator lamps instead of small incandescent bulbs. Modern LEDs are available in a broadband wavelength across the ultraviolet (250-380 nm), visible (380-760 nm) and infrared (760-1000 nm), which have been becoming popular due to their high efficiency and brightness. Nowadays, LEDs are used anywhere, such as indicators and signs, LCD backlight, displays, indoor and outdoor lighting, traffic lights, greenhouse lighting, etc.

LED is a small semiconductor light source (less than 1 mm²), including a two-lead p–n junction, reflectors, phosphors or integrated optical components to create light and shape its radiation pattern. The p–n junction is a boundary between two types of semiconductor material inside the same crystal. Like the common diode the p-n junction only allows electrical current to pass through in one direction (from positive to negative), which is called forward-biased. The color of the light emitted is determined by the semiconductor materials and the impurities of the junction.

An electron hole exists where an atom lacks electrons (negatively charged) and therefore has a positive charge. With a suitable voltage or current, electrons are able to recombine with electron holes within the semiconductor, releasing energy in the form of photons. This effect is called electroluminescence. The color of the light corresponds to the energy of the photon, which is determined by the energy bandgap of the semiconductor.

The total cost of a lighting system includes the initial purchase price, the cost of electricity and the cost of replacement. In the past, LEDs were often too expensive for most lighting applications. Even though the price of LEDs has significantly decreased over the last few years, it is still much higher than the price of legacy lighting sources. However, this higher initial cost can be offset by longer lifetimes and better energy efficiency . Yet since the life cycle savings are not guaranteed at the time of lighting system selection, higher initial costs are still an obstacle to the acceptance of LED lighting. According to a study by Samsung, the selling price of a white LED lighting system needs to decrease by 50% in order to make LEDs more competitive with fluorescent lamp systems over the next 4–5 years.

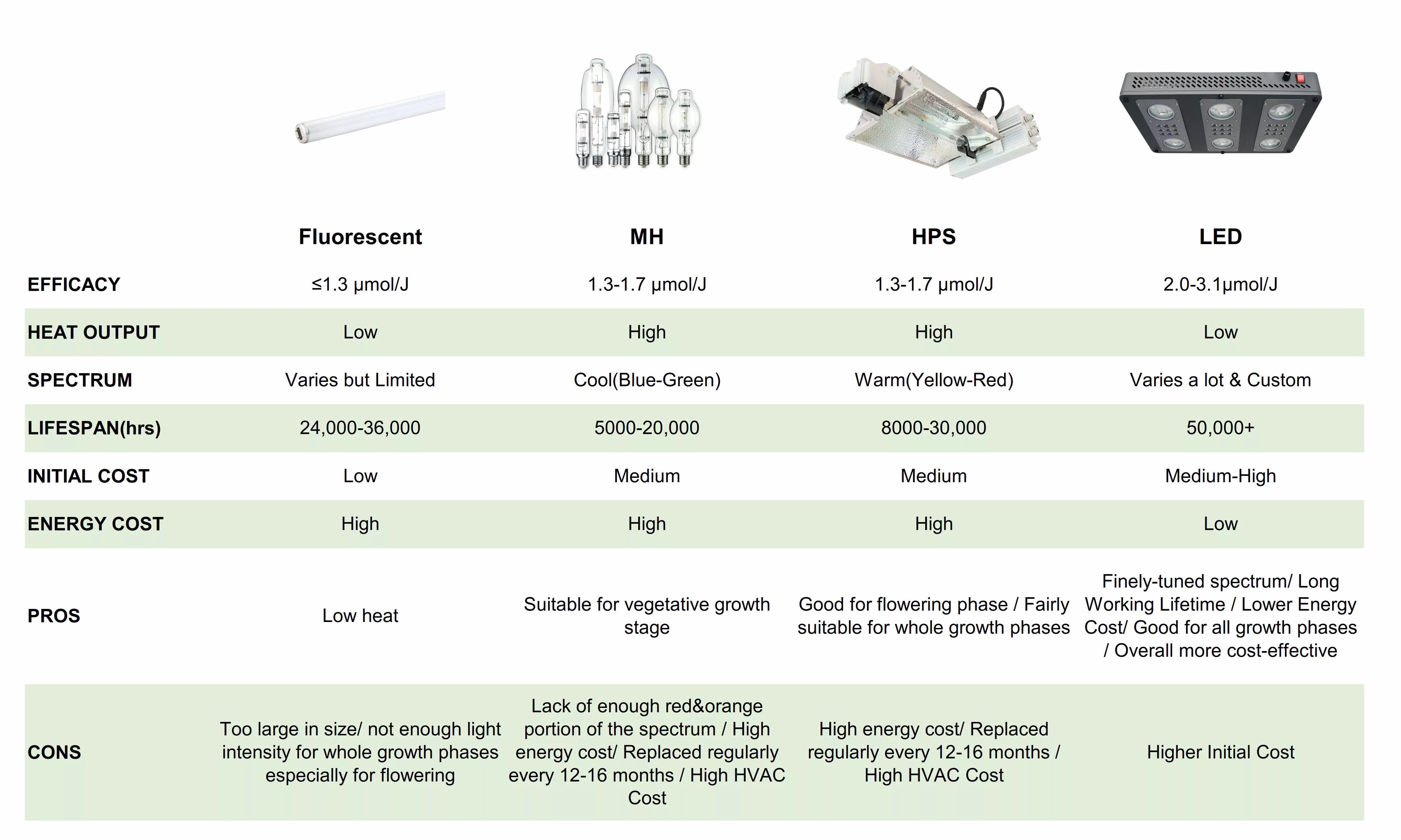

2.Comparison of Different Light Sources

Each of these four generations of different artificial light sources has made great progress. But from an overall consideration, LED grow lights has more obvious advantages than legacy light sources. First, LEDs can directly convert the electrical energy to light rather than producing lots of heat by a superheated filament, ionized gas, or arc discharge. So they can save up to 90% energy compared to a legacy bulb with the same light output. Besides, the meantime to failure (MTTF) of LED can be up to 10 times longer than that of legacy light source, avoiding the hassle of frequent changing of light bulbs. This significantly reduces waste but also saves money in the long term. Besides, various color and color temperatures from 2700 to 30,000K are available, as well as saturated colors. They are solid-state devices, which are much more robust than any glass envelope lamp and contain no hazardous materials like fluorescent lamps.

Comparison Of Different Grow Lights

2.1 Suitability of Different Light Sources In CEA(Controlled Environment Agriculture)

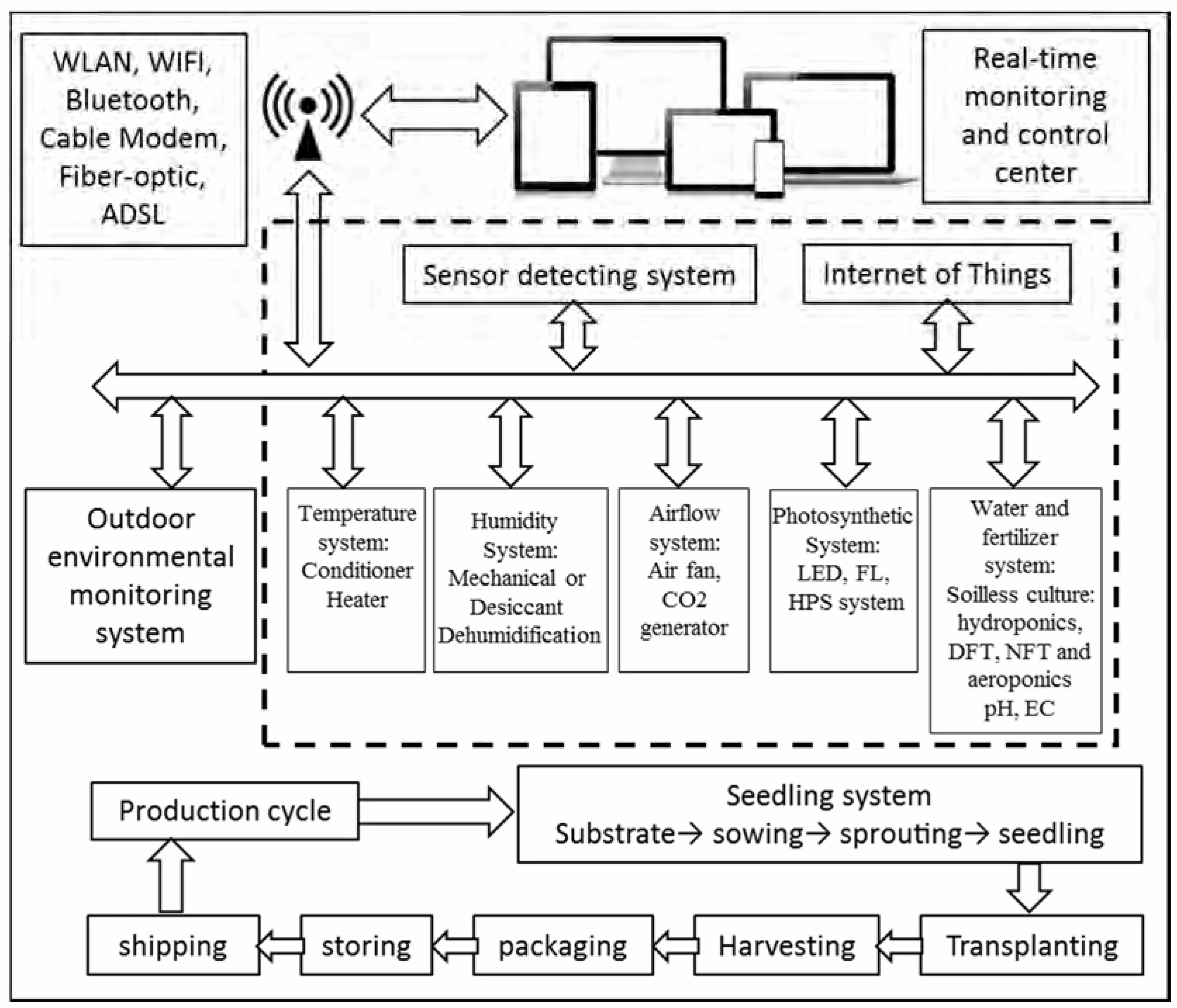

In order to effectively manage growing conditions, CEA farmers typically engineer technological systems by controlling for several factors that influence the growth rate and health of crops. These factors most often include:

Temperature (air, nutrient solution, root-zone)

Humidity

Carbon dioxide

Light (intensity, spectrum, interval)

Nutrient concentration

Nutrient pH (acidity)

CEA Systems

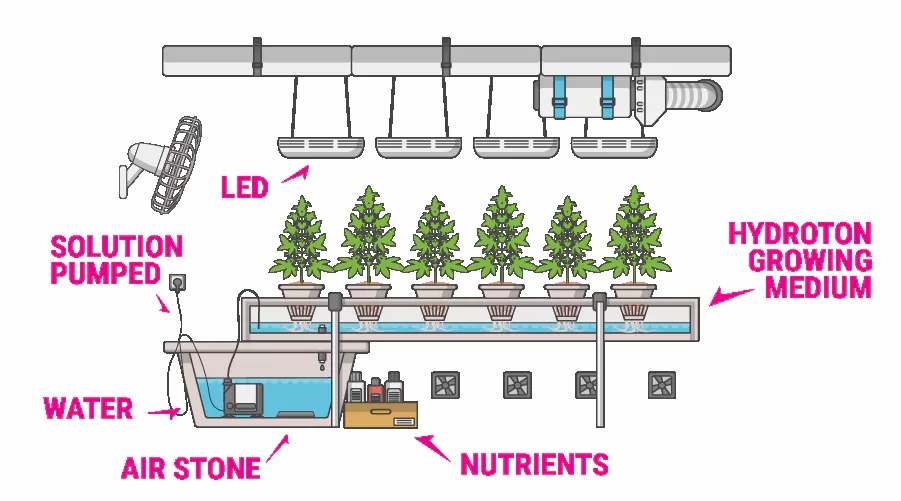

Over time, several forms of such technologies have been experimented with, and refined, to the point where they are now commonly applied within CEA operations. Some notable examples of CEA technologies are the frequently publicized methods of hydroponics, vertical farming, and LED light growing.

2.1.1 Legacy Light in CEA

Legacy light sources in CEA include the incandescent lamp, fluorescent lamp, high pressure sodium lamp and metal halide lamp, especially fluorescent and high pressure sodium lamps have been the most widely used PARS until now. However, most legacy PARS cannot be fully competent due to their characteristics and limitations.

First, the low electrical efficiency and large power consumption. The light energy costs account for about 60% -70% of the total electricity costs. It is mainly manifested by the low electro-optical conversion efficiency, such as high pressure sodium (HPS) lamp only 30%, fluorescent lamp 40%. Most of the energy is released as heat, thereby resulting in temperature rises, and increasing consumption of energy cooling systems (air cooling or air conditioning systems).

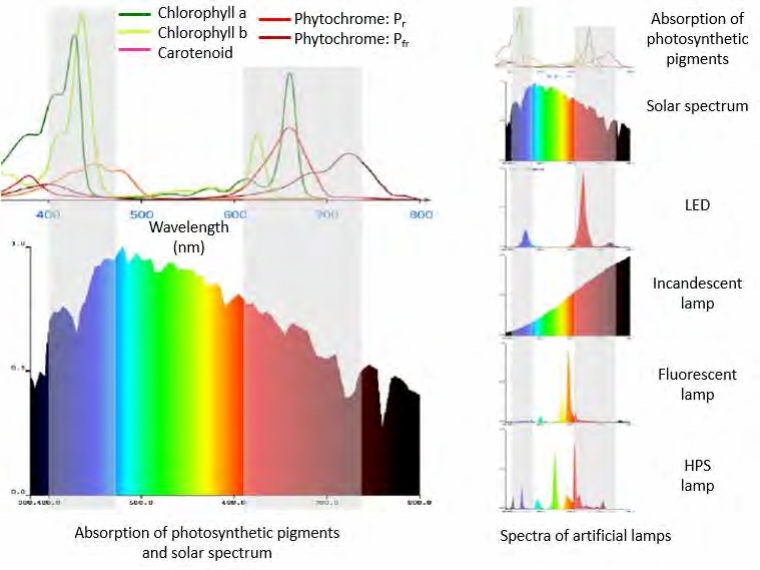

Second, less effective spectral power distribution (SPD). The SPD of legacy light is relatively fixed and different to adjust. It has many invalid or inefficient wavelengths, which cannot perfectly match the selective absorption spectrum of plants.

Third, large radiant heat. The legacy lights emit lots of infrared spectra, which spread in the form of heat. For example, the temperature of high pressure sodium lamps can reach 200 ℃, so when this kind of light is close to plant leaves, it is sure to burn the plants, causing plants dysplasia and even death. So legacy lights cannot illuminate the plants in a short distance.

2.1.2 LED light in CEA

LED is a kind of solid-state lighting; its applications in protected horticultural is one of the greatest advances over the past few decades; its wide applications have landmark significance. In 2013, according to industry analyst of Wintergreen Research, the output of world LED lamps for plant factory was up to $ 1.2 billion, a 27% increase over 2012.

LED in CEA

LED is a kind of sustainable lighting and an ideal alternative for plant growth. It can directly convert electrical energy into light energy. According to the latest report, LED has a remarkable energy-saving effect. The electro-optical conversion efficiency can reach up to 60%, much better than HPS lamp: 30%, fluorescent lamp: 40%. LED can be powered by a flexible DC power supply. It can easily realize intelligent control of light quality, intensity, and photoperiod, which is very difficult to realize for legacy light sources. Due to its optical characteristics and spectral advantages, LED light sources cannot be matched by a legacy source in plant production. LED is an ideal source for agricultural production. The advantages of LED grow light are mainly reflected in the following points:

A. LED grow light is more efficient than legacy light. The SPD of LED can be customized and adjusted according to the selective absorption spectrum of plants;

B. LED as a cold light source can illuminate close to the plants, which improves space utilization;

C. LED uses DC power, so it can be easily controlled and adjusted for optimal light intensity, quality and photoperiod, suitable for large scale and industrial production;

D. Its own advantages such as small size, lightweight, solid material, monochromatic light, energy saving, long life, environmentally friendly, durability, safe, etc.

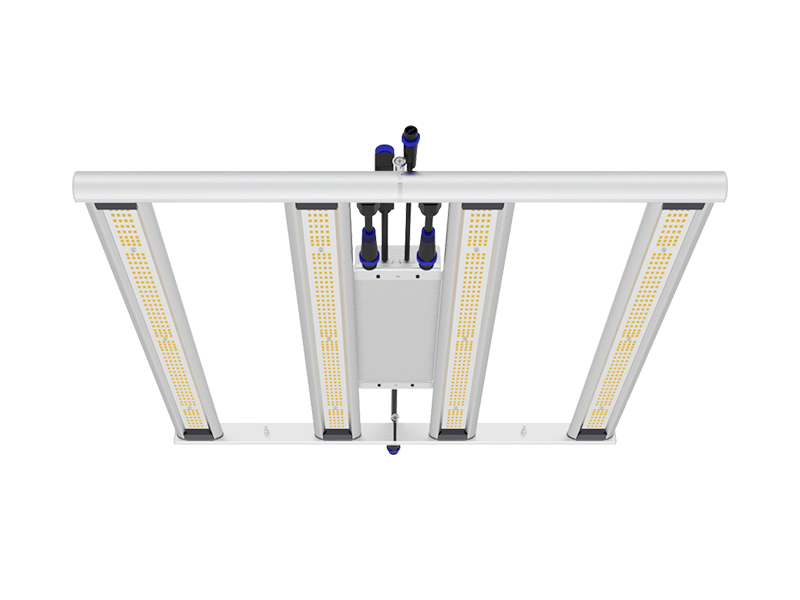

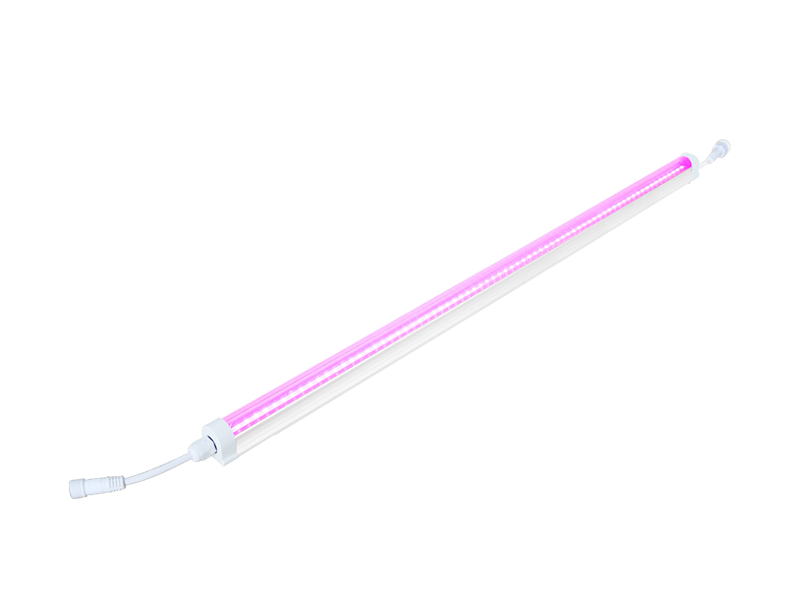

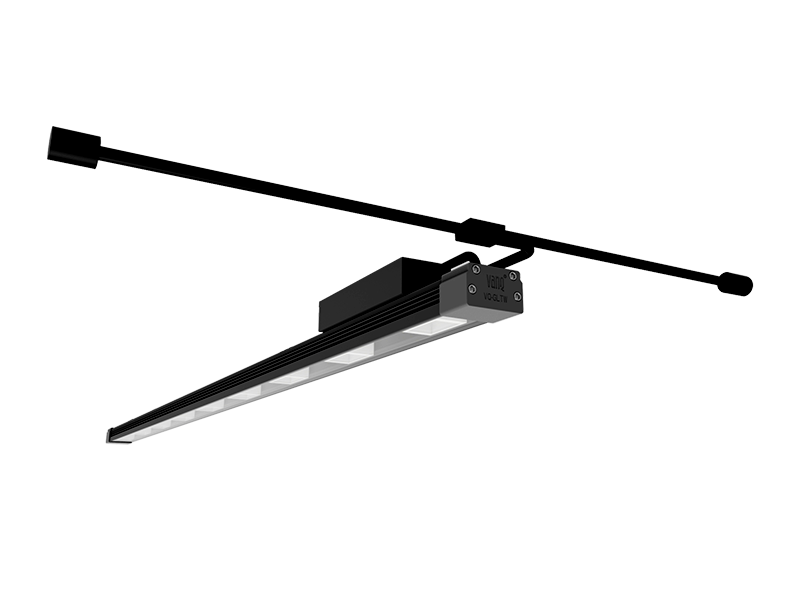

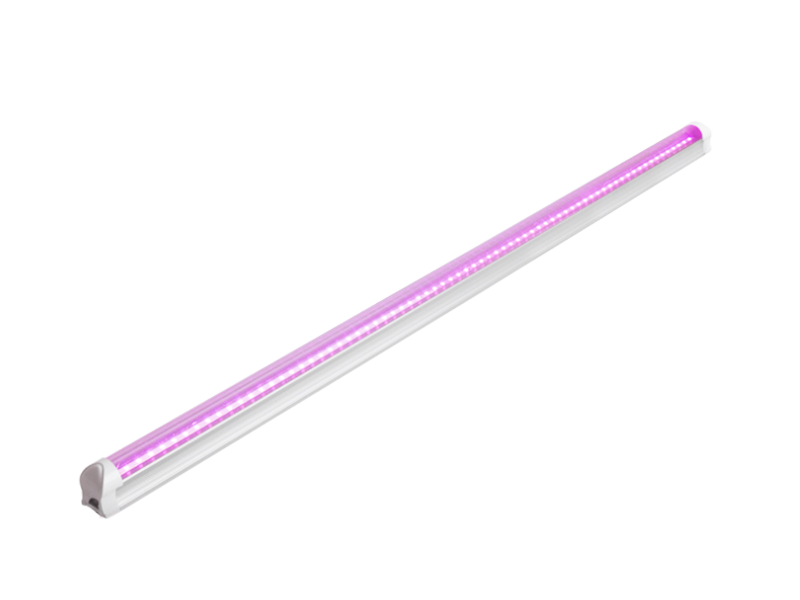

E. LED light source device has many varieties (light board, strip light, light tube, and light bulb), which is suitable for protected horticulture in various fields;

F. LED light source is an effective tool to study photobiology. The monochromatic LED test system can reveal the biological characteristics as the foundation of LED applications in plant factories.

Energy consumption as the main operating costs is an important reason for the high cost of running plant factories. Therefore, reducing the energy consumption of the lighting system has become the main way for energy saving. Taking a plant factory as an example, the lighting system is the largest energy consumption, accounting for more than 60%; the air conditioning system is the second one, accounting for more than 30%. Although LEDs have many advantages, LED light systems for plant growth should be designed properly to get the best performance and lifetime. LEDs do not radiate heat directly but do produce heat, so heat sink should be used to dissipate the heat. Last but not least, because LEDs are directional light sources, external optics are necessary to create the desired spectral power distribution.

Currently, plant factory used LED technology is mainly mastered by a few developed countries, such as Japan and the Netherlands. The spread and application of LED in protected horticulture exist the following obstructions.

2.2 Plant Photosynthesis With Different Light Sources

Photosynthesis is the most fundamental and important chemical reaction in the world, without that all life on Earth will disappear. It is deeply affected by environmental factors. In the final analysis, all the factors controlled in CEA (ventilation, heating, thermal screens or shade, humidification, recirculating) are to promote photosynthesis.

Light is an essential part of the reaction. It plays a critical role and has a direct effect on photosynthesis. Light control strategy has a profound significance for the development of protected horticulture.

Photosysnthesis of LED

Based on the analysis of the previous sections, The spectra offered by fluorescent or HID lamps cannot be adjusted specifically for plant growth. Typically a mass of wavelengths is emitted, yet very few of those wavelengths truly benefit the plant’s photosynthetic rate. LED light source is the ideal choice of plant production and has the potential to produce the most photosynthetically efficient light. So we mainly talk about the control strategy for LED light. Properly configured horticulture LED light systems provide plants with the optimal light treatment they need and therefore get the best growth and best production. For the greenhouse, the light transmittance is a basic evaluation index. The transmittance of the greenhouse is the ratio between the amount of incident light before and after into the greenhouse, which is influenced by transmission properties of covering material and the rate of skeleton shadow. With the different angles of solar radiation in different seasons, greenhouse transmittance is subject to change. In general, the transmittance for the multi-span plastic greenhouse is 50% to 60%, for the glass greenhouse, it is 60% to 70%, for solar greenhouse it can reach more than 70%. For energy-saving solar greenhouse, it is generally 60% to 80%. The greenhouse transmittance becomes a direct impact factor on crop growth and selecting the plant species. when the light is insufficient, supplemental light should be used to extend the exposure time. The light intensity can be adjusted automatically according to real-time light intensity, and suitable for plant growth. For plant factory, all the light environment is created by artificial light sources, so in addition to the control of light quality, quantity and photoperiod, the plant needs at different stages should also be considered. Intelligent control systems of light environment comprise LED light sources, sensors, computers, etc. Related adjustment should be performed to get the best light environment. Finally realize three objectives: low energy consumption (energy efficient), good quality and high yield.

2.3 Photobiology Research With Different Light Sources

Photobiology is the study of the relationship between light and biology (animals, plants, microorganisms). It is a multidisciplinary field including biology, chemistry, and physics. It aims to clarify how the light information affects organisms, as well as the mechanism of a biological reaction to light.

Photobiology Study

LED-based photobiology research is the basis of light regulation and a multi-discipline crossed new areas. The narrow spectrum of LED has the potential to clarify the relationship between plant varieties, light environment characteristics, photomorphogenesis, physiology, biochemistry, and molecular biology. It can provide a scientific basis for LED lighting design and light environment regulation. Plants need to be focused on the individual study from multi-angle. Particularly in the LED light quality and plant photosynthetic physiology, plant nutrition, and plant metabolic physiology. There are many issues should be discussed and clarified in plant molecular biology.

Photosynthetic Absorption Of Light Spectrum

Compared with the selective spectrum of plant pigments, only LED can provide a more efficient spectrum in the blue and red range. The combination of LED spectra has the potential to produce the optimal spectrum for specific species.

Lighting recipe (LR) and light environment control strategy (LECS) is the precondition to get the maximum energy efficiency under the premise of high yield and quality. With high yield and quality as the goal, LR refers to a parameter set that contains all the light information database (light quality, quantity, photoperiod, etc.) for the growth and development of particular plant species in different growth stages. Light quality in LR contains visible light quality, UV and far-red light, of which blue and red light are essential for plant production, and the others are beneficial light. LR is the basis for intelligent control of light sources and light environments, the establishment of the LR database has great significance in plant factories with artificial (or electric) lighting (PFAL). LECS is a method to direct control and switch the light environmental parameters through the computer-based on LR in different growth stages.

3. Conclusion

Artificial light technology is a core technology used in controlled environment agriculture, which can replace the unique sun light for photosynthesis. After the thorough comparison of the defects of each artificial lighting system, characteristics and electroluminescence mechanisms of legacy and modern artificial light sources, LED is proved to be the ideal light source for plant growth.

The LED lighting system can dynamically adjust the light quality,quantity and photoperiod in the practical applications. Growers can harness the LED technology advantage to grow higher quality crops as well as higher yield comparing to legacy lighting systems.

LED grow lights have much higher efficacy about 2-3 times than legacy light sources, longer life time up to 2-5 times than legacy light sources. Through the initial cost of LED is higher than HPS, MH, Fluorescent, the long-term cost saving on energy, lights replacement, manual labor, HVAC cost, etc makes LED a more competitive choice than traditional lights.